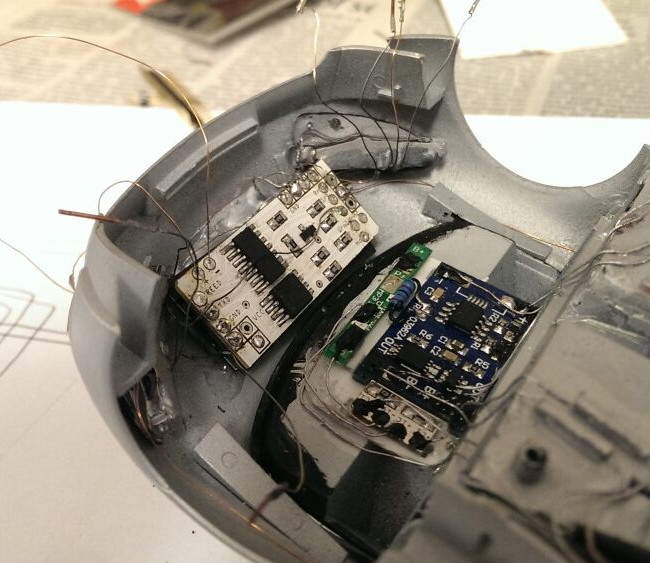

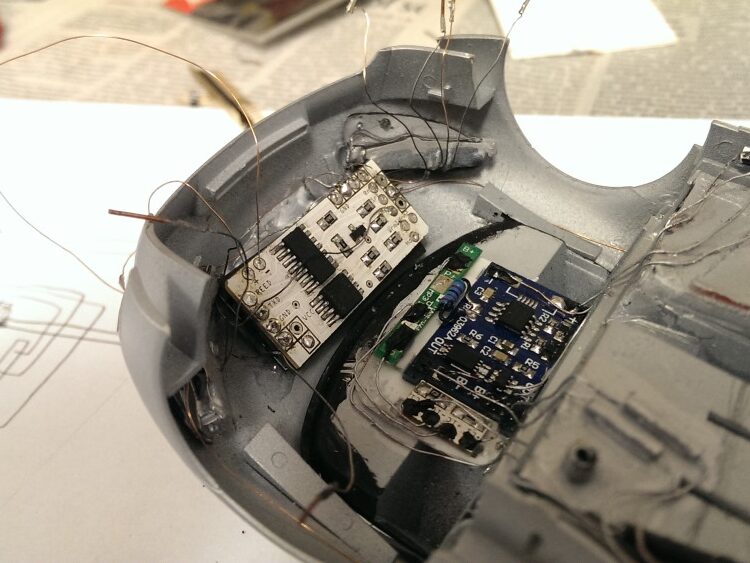

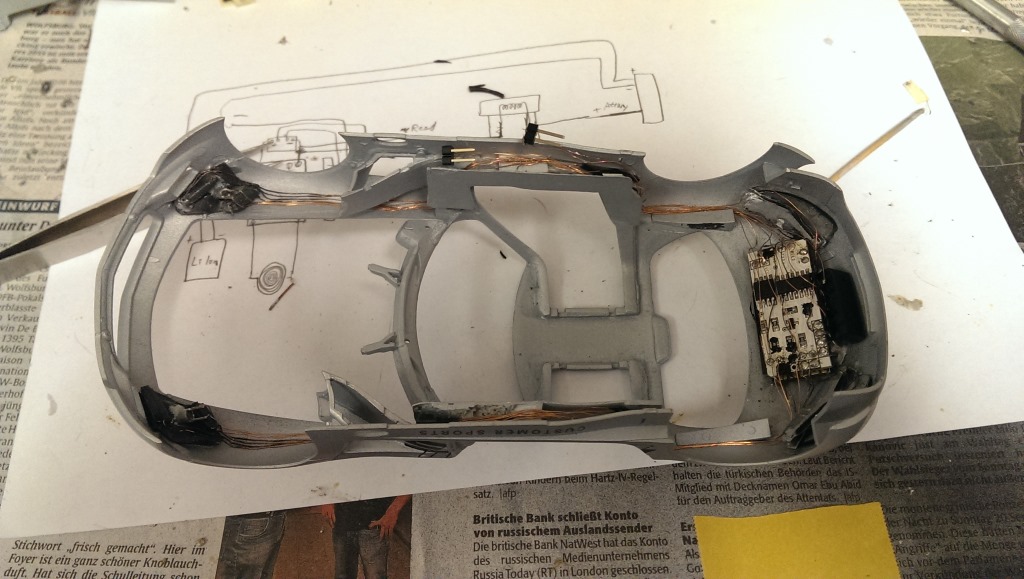

After the body was finally painted, the rest of the electronics could be integrated. The front and rear lights, the main PCB together with the Bluetooth module and the magnetic power switch were glued in. Enamelled coper wires are used to connect everything. These wires are very thin and isolated by a thin enamel coating. This coating can partially be scratched or melted away for soldering.

In one of the above pictures you can see the battery charging and protection circuit attached to the cockpit section. It can’t be directly connected to the main PCB because the cockpit will be attatched to the underbody prior to the bodywork. This also means that no easy soldering together of the wires is possible. The best way of connecting the two halfs of the car was to use plugs on the bottom of each side of the car, directly beneath the doors. Just before gluing the bodywork onto the rest of the car, the connectors can be plugged together.

A first test of the bodywork-electronics was successful and everything looks fine and seems to work…

– Project Page –